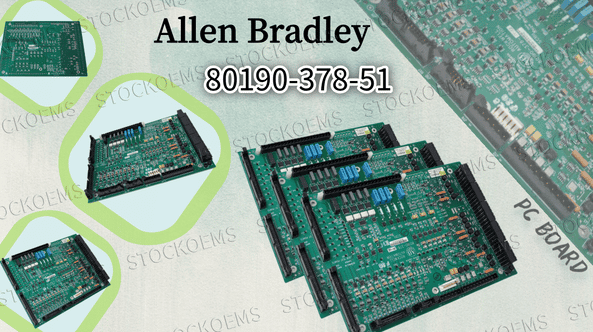

The Essential Role of Allen Bradley 80190-378-51 in Modern Automation

The Allen Bradley PC Board 80190-378-51 stands at the forefront of industrial automation technology, engineered to provide superior performance in the world's most challenging production environments. This advanced control module serves as the central nervous system of contemporary automated operations, delivering exacting management of intricate industrial processes across diverse sectors. Functioning as a crucial bridge between control networks and field equipment, the 80190-378-51 guarantees flawless communication and functionality in settings where absolute precision and dependability are mandatory. Its industrial-grade design allows continuous operation under extreme circumstances, including severe temperature fluctuations, high-vibration areas, and electrically disruptive conditions that would impair inferior systems. The distinguishing feature of this solution lies in its dual capability to sustain operational stability while providing instantaneous data for process refinement, establishing it as an essential component for enterprises aiming to upgrade their automation systems while reducing equipment failures and service interruptions.

Sector-Specific Advantages of This Cutting-Edge Automation Component

Multiple industrial sectors have increasingly adopted the 80190-378-51 Allen Bradley PDF to address their most demanding automation challenges. Within vehicle production facilities, this technology maintains the micrometer-level accuracy needed for modern assembly processes, where microscopic variations can result in substantial product defects. Pharmaceutical manufacturers value its contamination-resistant construction and exacting control functions, critical for adhering to rigorous quality standards in medication production. Food and beverage plants utilize this system to guarantee sanitary processing conditions and uniform output quality, while petroleum extraction operations count on its heavy-duty engineering to survive punishing field conditions. The application spectrum extends further to include municipal water purification systems, energy production stations, and microelectronics fabrication plants - virtually any operational environment where trustworthy, high-precision automation determines both success and safety. This component's adaptable nature permits customization to meet unique industry demands while preserving its fundamental performance attributes.

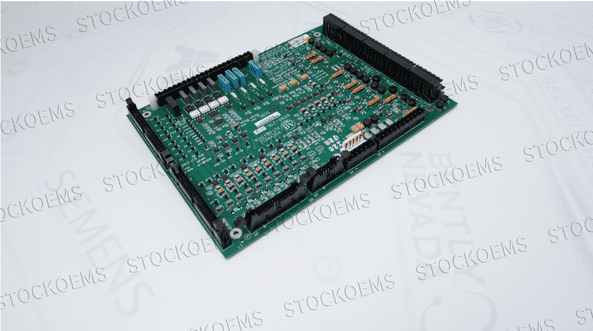

Best Practices for Deployment and Ongoing Management

Successful incorporation of the PLC-5 System Allen Bradley 80190-378-51 demands meticulous preparation to fully realize its advantages. Professionals integrating this technology must thoroughly evaluate facility-specific operational variables, encompassing ambient conditions, electrical specifications, and data transmission standards. The implementation sequence commences with comprehensive analysis of existing infrastructure capabilities and pinpointing optimal integration nodes where the 80190-378-51 can deliver performance enhancements. Configuration specialists must carefully program the unit's operational parameters to match precise application needs during the activation phase. While engineered for minimal servicing, the system benefits from scheduled performance evaluations to maintain peak functionality, with its durable architecture substantially decreasing upkeep requirements relative to traditional alternatives. Comprehensive workforce education on operational protocols and diagnostic methods constitutes a vital element of the adoption process, empowering technical staff to utilize the system's sophisticated capabilities while preventing production interruptions.

The Strategic Value of Allen Bradley 80190-378-51 in Evolving Industrial Landscapes

The 80190-378-51 Allen Bradley exemplifies the progressive advancement of industrial automation, delivering enterprises a dependable, high-caliber solution for their most rigorous control applications. Its fusion of industrial-strength construction, pinpoint accuracy, and next-generation connectivity establishes it as the preferred option for organizations pursuing operational modernization without compromising quality or productivity benchmarks. As production ecosystems grow more sophisticated and interconnected, technologies like the 80190-378-51 will assume greater importance in safeguarding business continuity and market competitiveness. For corporations investing in automation infrastructure upgrades, this component presents a forward-looking solution capable of evolving with technological progress while providing steadfast, predictable operation. Choosing the Allen Bradley 80190-378-51 fundamentally signifies an investment in manufacturing excellence, equipping industrial enterprises with the technological resources necessary to prosper in our rapidly automating world.

If you want to know details,please contact me without hesitate.