The Backbone of Modern Industrial Automation

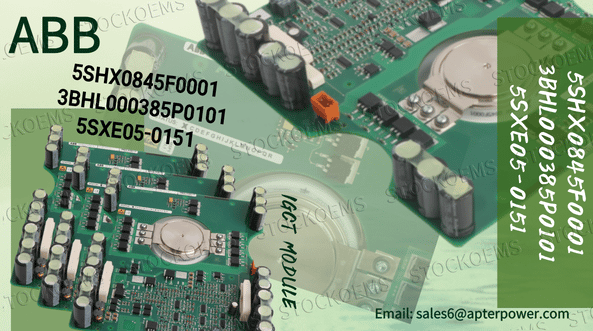

In manufacturing facilities worldwide, a quiet revolution is taking place as ABB's advanced component trio - the 5SHX0845F0001 3BHL000385P0101 5SXE05-0151 - redefine what's possible in industrial automation. These engineering marvels work in concert to deliver unprecedented levels of control and efficiency across diverse industrial applications.

Field technicians often describe the 5SHX0845F0001 IGBT module as the "muscle" of motor drive systems, handling power conversion with remarkable efficiency. Meanwhile, the 3BHL000385P0101 control board acts as the "brain" of ABB's renowned ACS800 drives, processing complex operational data in real-time. Completing this technological symphony, the 5SXE05-0151 serves as the "nervous system," facilitating seamless communication between various automation components. This powerful combination has become particularly valuable in harsh industrial environments where equipment must withstand extreme conditions while maintaining precision performance.

Why Industry Leaders Choose These ABB Components

Industrial operations managers face constant pressure to boost productivity while reducing costs and downtime. This is precisely where ABB's component trio delivers tangible value. In a recent case study at a major steel plant, implementation of these modules resulted in a 17% reduction in energy consumption while increasing production output by 12%.

What makes these components truly stand out is their intelligent design. The 3BHL000385P0101 control board, for instance, incorporates adaptive algorithms that automatically adjust motor parameters based on real-time load conditions. Maintenance teams particularly appreciate how the 5SHX0845F0001's advanced thermal management extends component lifespan, while the 5SXE05-0151's diagnostic capabilities help predict potential issues before they cause downtime.

In water treatment plants, these benefits translate to more reliable pump operations and significant energy savings. One facility reported saving over $200,000 annually in electricity costs after upgrading to systems incorporating these ABB components, while simultaneously reducing maintenance expenses by nearly 30%.

Transforming Industries Through Precision Control

The versatility of these ABB components becomes evident when examining their diverse applications. In offshore oil platforms, where equipment reliability is critical, these modules ensure consistent operation of vital pumping systems despite challenging marine conditions. Mining operations benefit from their ability to maintain precise control of massive conveyor systems hauling thousands of tons of material daily.

Renewable energy applications present another compelling use case. Wind farm operators report that systems utilizing these ABB components achieve more stable power output during gusty conditions, thanks to the rapid response capabilities of the 5SHX0845F0001 IGBT module. Solar installations similarly benefit from the precise maximum power point tracking enabled by this technology.

Automotive manufacturers have found particular value in implementing these components in their robotic assembly lines. The combination of precise motion control and energy efficiency allows for faster cycle times without compromising on precision or significantly increasing power consumption. One automotive plant achieved a 15% increase in production throughput while actually reducing its energy usage per vehicle produced.

The Future of Smart Manufacturing

As industries worldwide accelerate their digital transformation, these ABB components are proving to be essential building blocks for Industry 4.0 implementations. Their ability to provide detailed operational data supports the development of digital twins and enables more sophisticated predictive maintenance strategies.

Forward-thinking manufacturers are already leveraging these capabilities to create more flexible production systems. The components' interoperability with various industrial protocols makes them ideal for hybrid environments where new smart technologies must work alongside legacy equipment.

Looking ahead, the continued evolution of these technologies promises even greater integration with cloud-based analytics platforms and AI-driven optimization tools. This positions businesses using these ABB components at the forefront of the next wave of industrial innovation, ready to capitalize on emerging opportunities in an increasingly connected and automated industrial landscape.

If you want to know details,please contact me without hesitate.