Why Predictive Maintenance Solutions Are Essential for Industrial Operations

In the industrial sector, sudden equipment failures often have serious consequences. Last year, a sudden compressor failure at a large chemical plant caused a three-day shutdown, resulting in direct losses exceeding 5 million yuan. Such incidents have prompted companies to actively seek reliable predictive maintenance solutions. The Bently Nevada 330703 series vibration probes were developed precisely to meet this market demand. Their core eddy current vibrometer technology, based on the principle of electromagnetic induction, generates high-frequency electromagnetic fields during equipment operation, accurately capturing micron-level vibration fluctuations. In practical use at a hydropower station in Zhejiang Province, the system successfully provided early warning of cracks in a turbine runner, demonstrating accuracy unmatched by traditional monitoring methods. This innovative technology not only provides a "penetrating" view of equipment operating conditions but also identifies abnormal frequencies imperceptible to the human ear, providing reliable safety assurance for demanding industries such as power generation and petrochemicals.

How to Properly Install and Maintain the Monitoring System

Installation and commissioning of this system requires meticulous work by a professional technical team. While the equipment is shut down, engineers must select the optimal installation location, typically near bearing support points while avoiding any resonant areas. Through meticulous commissioning, a wind farm in Jiangsu Province successfully controlled monitoring errors to within 0.002mm. After the system went into operation, the maintenance team needed to regularly calibrate the baseline to ensure data accuracy. When vibration values exceed a set threshold, the system triggers both an audible and visual alarm in the control room and a text message alert. This comprehensive early warning system has proven effective at a power plant in Shandong, detecting potential faults an average of 30 days in advance, saving valuable time for equipment maintenance.

Where the Monitoring System Demonstrates Superior Performance

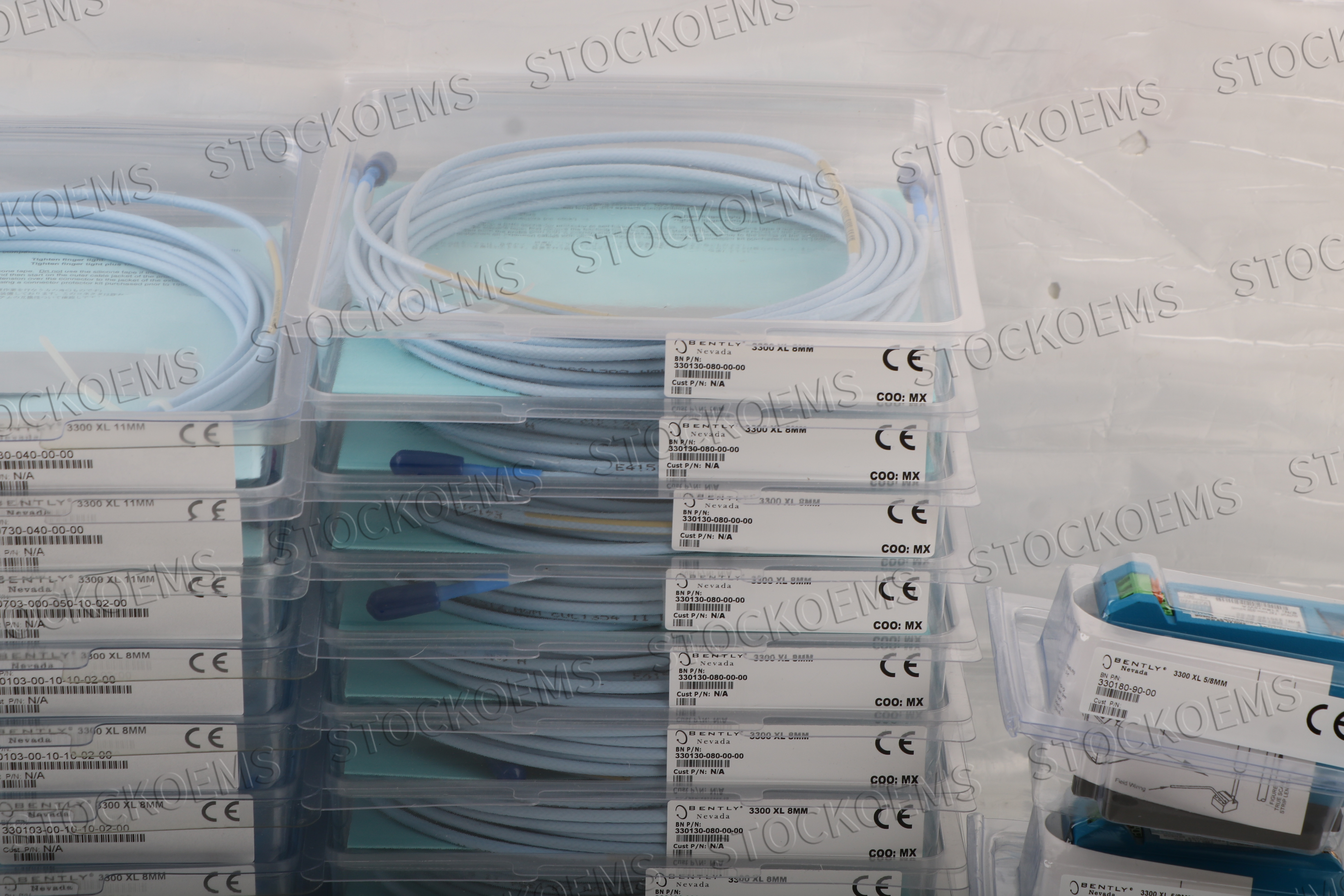

This Proximity Probes Bently Nevada 330703-000-100-10-11-05 demonstrates exceptional adaptability in various industrial environments. At oil pumping stations in the deserts of Xinjiang, the probes maintain stable operation despite summer temperatures reaching 50°C. At chemical plants on the southeast coast, specialized corrosion-resistant designs ensure optimal performance in humid, salt-fog environments. This technology is currently widely used in various sectors, including power generation, metallurgy, and mining, achieving particularly significant success in monitoring large rotating equipment. The Bently 3300 XL 11mm 330703-000-100-10-11-05's multi-level early warning mechanism is scientifically designed. A primary alert is triggered when vibration values exceed the baseline by 25%, while an emergency response plan is activated when the value reaches 50%. This tiered warning system ensures timely response while avoiding unnecessary production downtime caused by false alarms.

Who Utilizes the System and What Benefits It Delivers

This 3300 XL 11mm Proximity Transducer System 330703-000-100-10-11-05 Bently Nevada's users include equipment engineers, maintenance teams, and management personnel. Through professional training and technical support, users can fully utilize the system's effectiveness. At a manufacturing company in Liaoning, the trained technical team is now able to independently perform system maintenance and data analysis. The remote technical support provided by the equipment manufacturer complements the company's independent maintenance efforts. With the advent of the Industry 4.0 era, this monitoring solution, which integrates advanced sensing technology, intelligent early warning systems, and professional operations and maintenance, is reshaping industrial equipment safety management standards, providing solid technical support for companies' predictive maintenance and creating significant economic and safety benefits.

If you want to know details,please contact me without hesitate.

Recommended Model

| DDS02.1W050-D | 216-0BA00-2AA3 | 6ES5430-3BA11 |

| MCD201-015-T4-CV3 | 3TK2828-2BB40 | GX121-TFT8U-F0 |

| MDV60A00305A3400 | MP66L K16 469080/23 DC10R | SL-C20H SLC20H SL-C20H-T + SL-C20H-R |

| I34BB5154G18W61 | DAM11000 2CMA139255R1000 | LENZE MDSKSRS036-23 00394594 005939 |

| 1600RRRRI00001000 | 2600T 266GST FKTN B8 E1B7I1C15H3 | B&R X20 A0 4622 X20A04622 + X20 BM11 |

| VP744R7YZ104FMX538 | HBM U1 220.12-2003 23071 EXSG5 B/E-15313 | HBC SPECTRUM 2776-17 00553 + HBC BA225030 |

| LTS062P-15/10-GL-X001 | KOLMORGEN SERVOSTAR 341 S3010 1-NA | HBC SPECTRUM 1 524-16 01279 + HBC BA225030 |

| FESTO 170943 DFM-40-125-P-A-KF | D1VW026HNJEE91 D14-20870-29 014-20870-29 | SICK C4000 MICRO C40E-0601BG300 1023488 |