The VIBRO-METER VM600 TQ412 111-412-000-012 Proximity Sensor is a high-precision proximity measurement system from Meggitt's vibro-meter® line, designed for critical turbomachinery monitoring. This API 670-compliant solution combines a TQ412 reverse-mount sensor with advanced signal conditioning to measure shaft displacement and vibration in turbines, compressors, and pumps. The TQ412 111-412-000-012 Proximity transducer delivers exceptional accuracy across a 2-4mm measurement range with DC to 20kHz frequency response, making it ideal for both slow-roll and high-speed applications.

At the core of the Meggitt Vibro Meter TQ412 111-412-000-012 proximity sensor is a stainless-steel Torlon®-tipped transducer featuring a molded detection coil and integral coaxial cable. The temperature-compensated design maintains stability from -40°C to +180°C, while its reverse-mount configuration enables flexible installation in space-constrained environments. The system's electromagnetic field technology provides non-contact measurement of metallic targets with micron-level resolution, available in 1/5/10 meter cable configurations to suit various machine layouts.

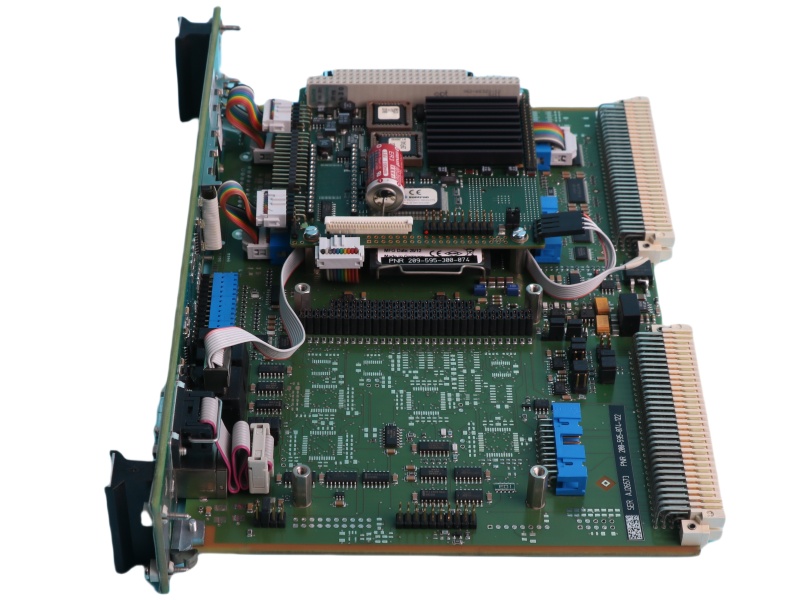

The VIBRO METER CPU card TQ412 111-412-000-012 pairs with IQS900 conditioners featuring SIL 2-rated safety architecture and enhanced EMI protection. These DIN-rail mounted units offer voltage/current outputs proportional to shaft gap distance, with optional BIST diagnostics for predictive maintenance. Improvements over previous generations include lower output impedance, test inputs, and removable terminals - all housed in rugged aluminum enclosures for industrial durability.

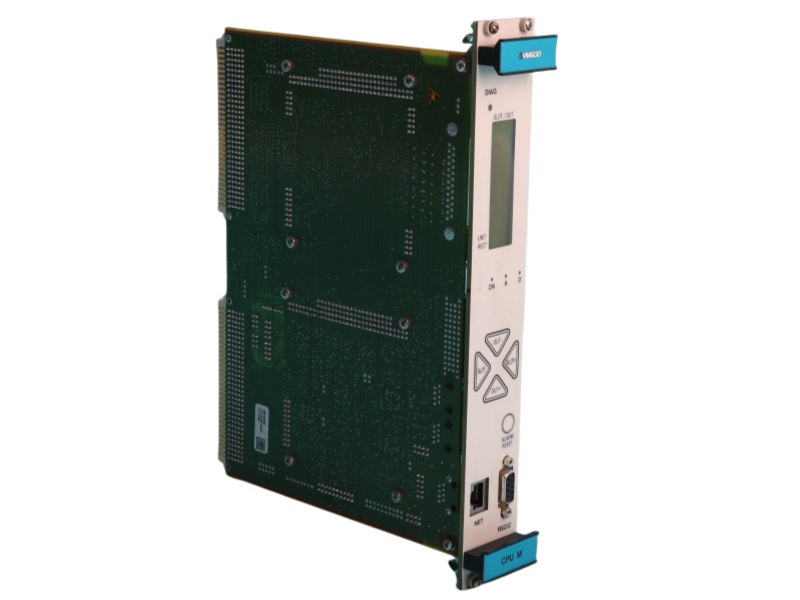

Engineered for seamless compatibility with VM600Mk2 monitoring systems, the Proximity System VM600 TQ412 111-412-000-012 supports both standalone and networked deployments. The compact 24.6×14.1×4.5cm package (0.32kg) ships from Xiamen with global certifications, ready for installation in power generation, oil & gas, and heavy industrial application.

For the quick assistance message us on WhatsApp at

For the quick assistance message us on WhatsApp at