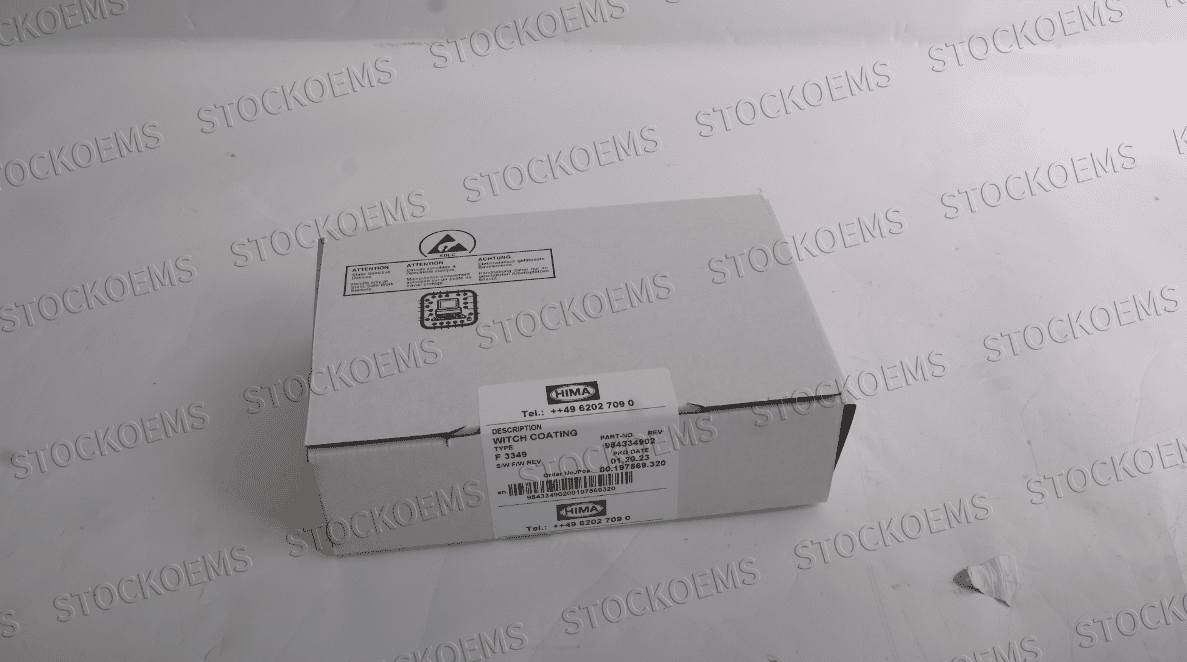

Introduction to HIMA F3349 and Its Role in Modern Industry

Industrial operations today demand safety solutions that can keep pace with increasingly complex environments and rigorous regulations. The HIMA F3349 Digital I/O Module safety control system has emerged as a critical solution, offering reliability and performance that set it apart in high-risk sectors. This advanced system meets the growing need for fail-proof safety mechanisms through its unique design and comprehensive protection features.

With HIMA's half-century of experience in safety systems development, the F3349 series represents a careful balance between technological sophistication and practical implementation. Its applications prove most valuable in industries where equipment failure carries severe consequences - particularly oil and gas operations, chemical manufacturing plants, and power generation facilities. The system's introduction coincides with global industries adopting more demanding safety standards, including the widely recognized IEC 61508 and IEC 61511 certifications.

Breakthrough Technology Behind the F3349 System

What makes the HIMA F3349 8-Channel Output Module stand out begins with its dual-channel redundant design, maintaining continuous operation even when individual components malfunction. This architecture has earned the system SIL 3 certification for all its safety functions. Engineers particularly appreciate its diagnostic system, which monitors critical components in real time with 95% fault detection capability. The incorporation of Ethernet-based safety protocols represents another leap forward, allowing smooth connection with modern control systems without compromising security.

The system goes beyond traditional safety approaches with its ability to predict maintenance needs by analyzing operational patterns. Its flexible setup supports configurations ranging from modest installations to extensive industrial complexes, handling up to 1,024 input/output points. Built to endure tough conditions, the F3349 operates reliably in temperature extremes from -40°C to +70°C and carries hazardous area certifications including ATEX and IECEx.

Proven Performance Across Critical Industries

Field data from various high-risk sectors demonstrates the HIMA F3349 Digital I/O Module's effectiveness. Offshore drilling operations using the system report 60% fewer safety-related production stoppages while maintaining perfect safety function availability. In chemical processing plants, the system's advanced sequencing has cut emergency response times by 40%. Power stations employing the F3349 have achieved nearly perfect safety system reliability at 99.9999%, surpassing typical industry performance levels.

The system delivers measurable advantages that impact both safety and operations:

Looking Ahead: The Evolving Role of Safety Systems

The HIMA F3349 H41q/H51q Systems marks more than just another safety product - it introduces a new way of thinking about industrial protection. As operational risks grow more complex and regulations continue to tighten, this system provides a solution that addresses both current needs and future challenges in safety management.

Companies that have implemented the F3349 report significant improvements in several areas: fewer safety incidents, less unplanned downtime, and reduced long-term costs. The system's ongoing development will incorporate more advanced features like artificial intelligence and cloud-based monitoring, ensuring it remains at the forefront of safety technology for modern industrial facilities.

For operations managers and safety professionals, choosing the HIMA F3349 Safety Module represents more than purchasing new equipment - it's a long-term commitment to workplace safety and operational excellence. The system's dual capability to prevent accidents while improving efficiency makes it essential for any operation where protecting people and processes is the top priority.

If you want to know details,please contact me without hesitate.