Understanding the Core Functionality of GE's Industrial Processors

In today's rapidly evolving industrial automation landscape, the IS215WEPAH2BDA General Electric PDF stand out as critical components for robust control systems. These specialized processor modules form the backbone of GE's Mark VIe Speedtronic series, designed specifically for gas and steam turbine management. The IS215WEPAH2BDA serves as a high-performance Windows Embedded processor, while the IS200AEPAH1BPH functions as an advanced application processor - together they create a powerful duo for industrial automation. These units operate by processing critical operational data, executing control algorithms, and communicating with other system components to ensure seamless turbine operation. Their importance becomes particularly evident in power generation plants where milliseconds of delay can translate to significant operational risks.

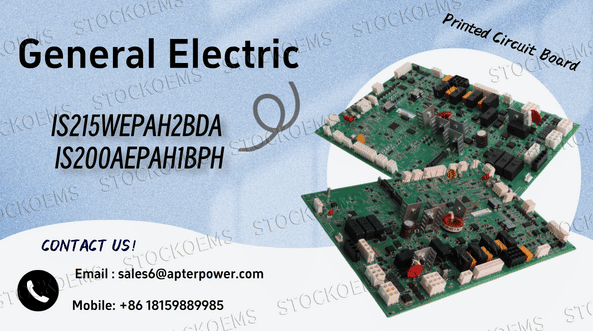

Key Features and Technical Specifications

The GE IS215WEPAH2BDA Printed Circuit Board IS200AEPAH1BPH distinguishes itself with its Windows Embedded operating system, providing a familiar interface for engineers while maintaining industrial-grade reliability. It features dual Ethernet ports for network redundancy, USB interfaces for local configuration, and robust processing power to handle complex control algorithms. Meanwhile, the Digital input module IS215WEPAH2BDA IS200AEPAH1BPH complements this setup with specialized application processing capabilities, including extensive I/O support and real-time data processing. Both modules are built to withstand harsh industrial environments, featuring wide operating temperature ranges and vibration-resistant designs. The hardware architecture incorporates fail-safe mechanisms and redundant communication paths, ensuring continuous operation even during partial system failures. These technical characteristics make them particularly valuable for applications requiring uninterrupted operation, such as in power plants where turbine control demands absolute precision and reliability.

Applications and Industry Impact

These GE processor modules find their primary application in power generation facilities worldwide, particularly in combined cycle plants and industrial turbine installations. The IS200AEPAH1BPH General Electric IS215WEPAH2BDA typically handles human-machine interface (HMI) functions and higher-level control tasks, while the IS200AEPAH1BPH manages real-time process control and equipment monitoring. Their deployment significantly enhances operational efficiency by enabling predictive maintenance capabilities and reducing unplanned downtime. In the field, these components have demonstrated particular value during plant startups and load changes, where their rapid processing capabilities help maintain grid stability. The modules' advanced diagnostics capabilities allow engineers to identify potential issues before they escalate, contributing to improved plant safety records. Furthermore, their compatibility with existing GE control systems makes them a preferred choice for facility upgrades, offering improved performance without requiring complete system overhauls.

The Future of Industrial Control with GE's Advanced Processors

As industrial automation continues advancing, the IS215WEPAH2BDA IS200AEPAH1BPH GE Mark VIE represent the cutting edge of control system technology. Their combination of robust hardware, sophisticated software, and proven reliability makes them indispensable components in modern power generation infrastructure. These modules not only address current industrial needs but also provide a foundation for future smart grid applications and Industry 4.0 implementations. For plant operators and automation engineers, understanding and utilizing these processors effectively can mean the difference between standard operation and optimized performance. As GE continues to innovate its Speedtronic series, these processor modules will likely remain at the forefront of industrial control solutions, adapting to meet the evolving demands of power generation and beyond. Their track record in critical applications underscores their value as essential components in maintaining efficient, safe, and reliable industrial operations worldwide.

If you want to know details,please contact me without hesitate.