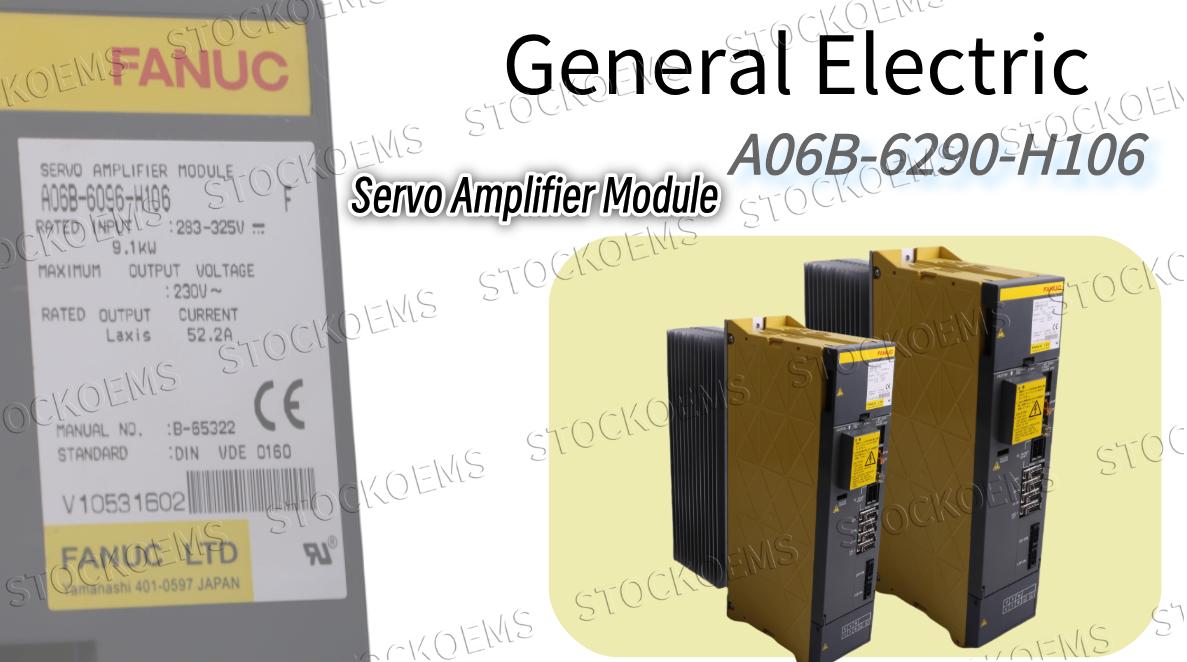

Introduction to GE A06B-6290-H106

A06B-6290-H106 Servo Drive/Servo Control by FANUC is a high-precision servo drive module developed by GE Fanuc, tailored for demanding industrial automation scenarios. As a core component of key equipment such as CNC machining centers, industrial robots and intelligent production lines, this product is known for its excellent stability and precise control performance, and has now become an indispensable part of the modern intelligent manufacturing system. Its innovative structural design and the integrated application of cutting-edge technologies are redefining the performance standards of industrial automation equipment.

Core Technology Advantages

The outstanding advantages of this drive module are reflected in three dimensions: first, the use of an intelligent energy consumption management system increases the energy efficiency conversion rate by more than 30% compared with traditional products; second, it is equipped with a nano-level motion control algorithm, and the position repeatability accuracy can reach ±0.001mm; third, it supports mainstream industrial communication protocols such as PROFINET and EtherCAT to achieve millisecond-level response between devices. It is particularly worth mentioning that its modular design supports plug-and-play with more than 90% of the servo motors on the market, and with a military-grade protective shell, it can maintain 100,000 hours of trouble-free operation even in harsh working conditions such as dust, oil, and vibration.

Industry application value

In the field of automobile manufacturing, A06B-6290-H106 Servo Amplifier Module ensures that the welding robot achieves a trajectory accuracy of 0.02mm; in the processing of aircraft engine blades, it can stably control the micron-level cutting of 5-axis linkage machine tools; in the 3C electronics industry, it provides a driving force for high-speed placement machines to accurately position 200 times per minute. As an Industry 4.0 standard certified device, its built-in predictive maintenance system can warn of potential failures 14 days in advance through big data analysis, helping multinational companies such as Tesla and Boeing to increase their overall equipment efficiency (OEE) to more than 92%.

Future development trends

With the integration of new technologies such as digital twins and edge computing, A06B-6290-H106 General Electric PDF is evolving into a neural node of smart factories. The latest firmware supports digital twin simulation debugging functions, and engineers can complete 90% of debugging work in a virtual environment. According to the International Society of Automation, by 2026, more than 500,000 devices of this model will be connected to the industrial Internet of Things worldwide, promoting the transformation of the manufacturing industry to a "dark factory". This epoch-making product not only redefines industrial control standards, but will also become a key enabler of the next generation of smart manufacturing revolution.

If you want to know details,please contact me without hesitate.