Understanding the Bently Nevada 9200-01-01-10-00 Vibration Monitor

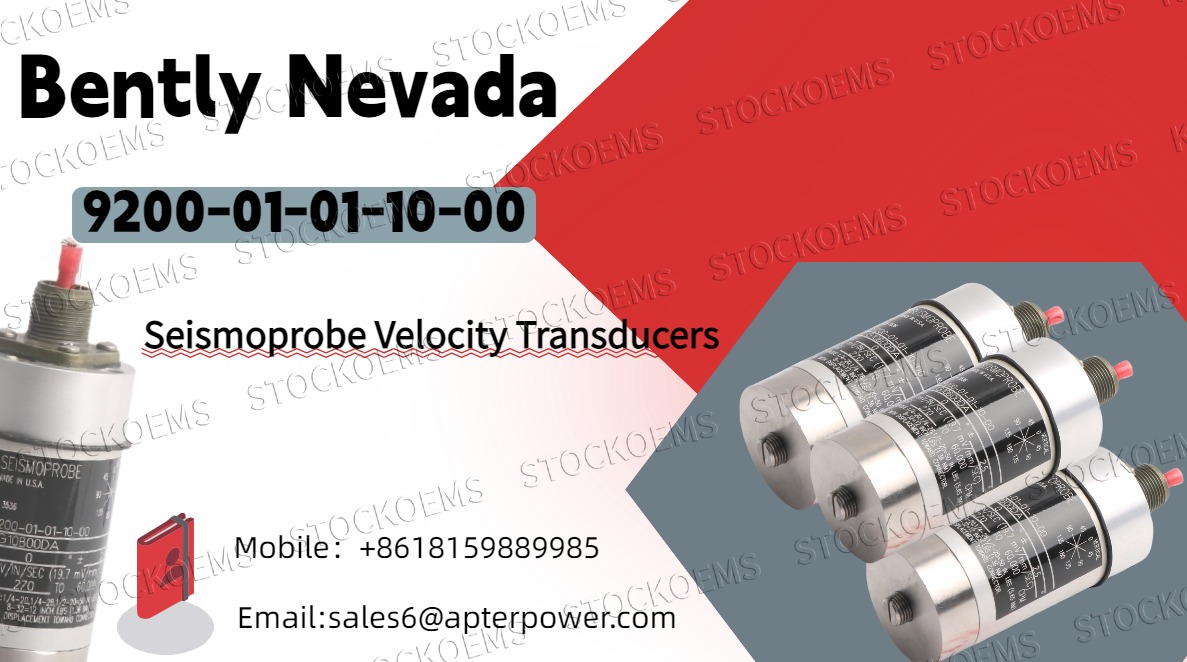

Bently Nevada 9200-01-01-10-00 Seismoprobe Velocity Transducers is a high-precision vibration monitoring module designed for industrial machinery and equipment protection. As a core product of Baker Hughes, a benchmark company in the field of industrial asset management, this device plays an irreplaceable and important role in the vibration and axial displacement monitoring of rotating machinery such as turbine units, compression equipment and pumps. This monitoring module belongs to the prestigious 9200 series product line and has won wide recognition from the global industrial community for its excellent reliability in key industrial application scenarios such as oil and gas extraction, power energy production and heavy manufacturing. The core function of this device is that it can continuously monitor the mechanical vibration state in real time and convert mechanical vibration into electrical signal data for analysis through precise sensing technology. Its unique value lies in its ability to accurately capture potential fault characteristics such as early equipment wear, shaft alignment deviation and abnormal rotor dynamic balance, thereby effectively preventing possible catastrophic mechanical failures and significantly reducing unplanned downtime and equipment maintenance costs.

Why Is the Bently Nevada 9200-01-01-10-00 Essential for Industrial Safety

Modern industrial production bases generally rely on the high-intensity continuous operation of large-scale key units, and these equipment often work under extreme conditions such as high temperature, high pressure, and high speed. Any sudden equipment failure may trigger a chain reaction, resulting in millions of dollars in production losses or even major safety accidents. The most outstanding technical advantage of this monitoring system is its perfect intelligent integration function, which can be deeply interconnected with core control systems such as factory DCS and SIS. When key parameters such as vibration amplitude and phase are detected to exceed the preset safety threshold, it can automatically trigger a multi-level alarm mechanism and even execute the equipment interlocking shutdown protection program. This intelligent solution based on the concept of preventive maintenance has fundamentally changed the drawbacks of traditional passive maintenance and built a comprehensive equipment safety protection system for modern industrial enterprises. What is more noteworthy is that this product supports mainstream industrial communication protocols such as PROFIBUS and Modbus, ensuring seamless connection with various existing equipment management systems. This excellent compatibility makes it an ideal choice for the construction of predictive maintenance systems in the era of Industry 4.0.

How Does the Bently Nevada 9200-01-01-10-00 Compare to Other Vibration Monitors

In the process of selecting industrial vibration monitoring equipment, professional users usually conduct comprehensive evaluation from multiple dimensions such as measurement accuracy, environmental adaptability, and system integration. Two-Wire Velocity Seismoprobe Transducer Manufacturer 9200-01-01-10-00 has shown obvious competitive advantages in these core performance indicators, enabling it to always maintain a leading position in the fierce market competition. Compared with conventional vibration sensors, the biggest technological breakthrough of this product is that it integrates advanced intelligent diagnostic functions, which can not only provide basic vibration amplitude monitoring, but also has advanced diagnostic capabilities such as phase angle measurement, order analysis, and waveform acquisition. These functions are decisive for accurately judging complex fault types such as rotor imbalance, shaft bending, and bearing defects. In terms of extreme environmental adaptability, this product uses a special alloy shell and military-grade electronic components, and has passed strict anti-electromagnetic interference, corrosion resistance, wide temperature range operation and other rigorous tests. Its environmental tolerance far exceeds the industry standard requirements. Most competing products on the market generally have zero drift problems after long-term operation and require frequent on-site calibration. However, Bently Nevada 9200-01-01-10-00 can ensure stable operation for years without manual intervention with its unique self-calibration technology and temperature compensation algorithm.

Where Does the Bently Nevada 9200-01-01-10-00 Play Its Critical Safety Role in Industry

On the whole, 9200-01-01-10-00 Transducer Systems Bently Nevada vibration monitoring module has surpassed the scope of traditional monitoring equipment and has become a key component of equipment health management in modern intelligent manufacturing systems. By providing high-precision and high-reliability real-time equipment status data, this product has laid a solid technical foundation for industrial enterprises to build a predictive maintenance system, and plays an irreplaceable role in reducing unplanned downtime, optimizing maintenance resource allocation, and improving factory safety levels. Whether in large combined cycle power plants, deep-sea oil platforms or modern automobile manufacturing plants, this product has won the widespread trust of users with its excellent performance. For industrial enterprises pursuing lean equipment management, choosing Bently Nevada 9200 series Transducer not only means adopting the most advanced vibration monitoring technology, but also represents a strategic investment in the long-term safe and stable operation of equipment. With the rapid development of industrial Internet of Things and intelligent manufacturing, this monitoring module that integrates cutting-edge sensing technology, intelligent diagnostic algorithms and industrial-grade reliability will continue to lead the technological innovation in the field of industrial equipment status monitoring.

If you want to know details,please contact me without hesitate.