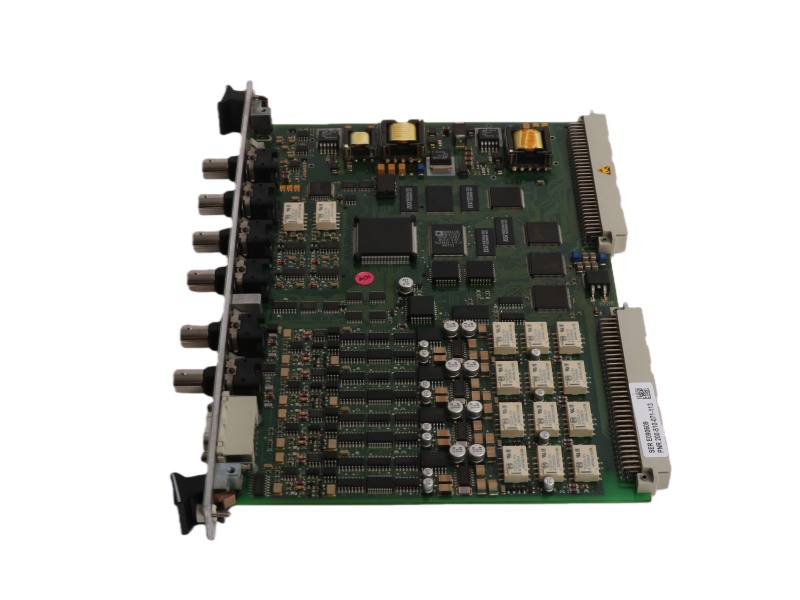

The VM600 MPC4 200-510-071-113 VIBRO-METER PROTECTION CARD serves as the central processing unit within the VM600 machinery protection system, delivering comprehensive monitoring capabilities through its sophisticated four-channel dynamic input architecture. This advanced protection card continuously processes signals from various transducer types including accelerometers, velocity sensors, and proximity probes while simultaneously monitoring two independent tachometer channels for complete rotational assessment. The engineering design of the PLC MODULE VM600 MPC4 200-510-071-113 incorporates state-of-the-art digital signal processing technology that enables real-time measurement of critical parameters including vibration amplitudes, phase relationships, and mechanical positions with exceptional accuracy.

Signal processing capabilities distinguish the VIBRO-METER MACHINERY CONTROL VM600 MPC4 200-510-071-113 through its programmable filter configurations that support both broad-band and narrow-band analysis tailored to specific machinery characteristics. The computational framework embedded within the module performs complex mathematical operations including integration, differentiation, and multiple rectification methods while providing order-tracking functionality that correlates vibration data with rotational speed for enhanced diagnostic precision. This sophisticated processing enables the module to monitor multiple physical parameters including SMAX, eccentricity, thrust position, and various expansion measurements through a single integrated unit.

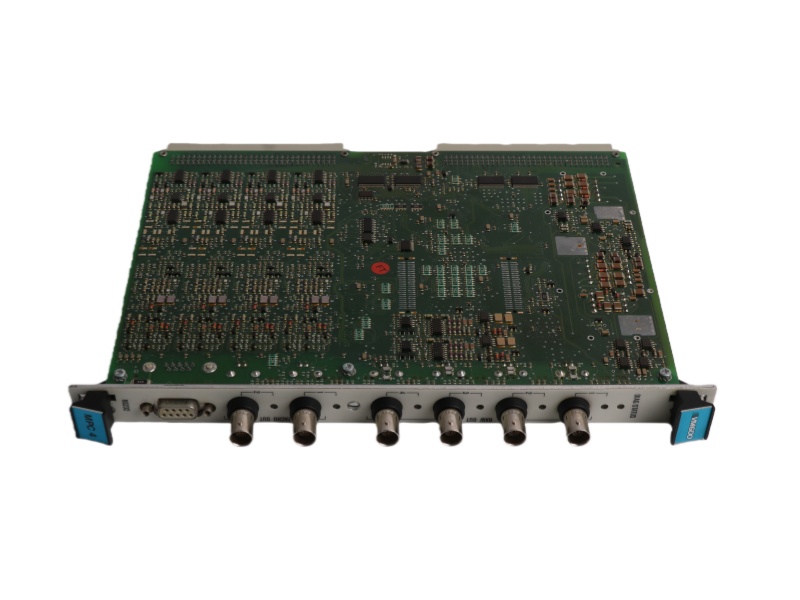

Operational flexibility defines the VIBRO-METER VM600 MPC4 200-510-071-113 through fully configurable alarm setpoints with adaptive capability that adjusts alert and danger thresholds based on operational conditions or external parameters. The front-panel design of it incorporates BNC connectors for direct signal access and LED indicators for immediate status assessment, while the hot-swappable architecture enables maintenance operations without system shutdown. These features combine to make it particularly valuable in continuous process applications where operational availability is paramount.

Implementation of the Machinery Protection Card VM600 MPC4 200-510-071-113 VIBRO-METER typically occurs in critical machinery protection applications across power generation, oil and gas, and industrial manufacturing sectors where reliable equipment monitoring directly impacts operational safety and productivity. The proven performance of the VIBRO-METER VM600 SERIES VM600 MPC4 200-510-071-113 establishes it as a trusted solution for protecting turbines, compressors, and other high-value rotating assets through continuous assessment of mechanical health parameters and immediate response to developing fault conditions.

For the quick assistance message us on WhatsApp at

For the quick assistance message us on WhatsApp at