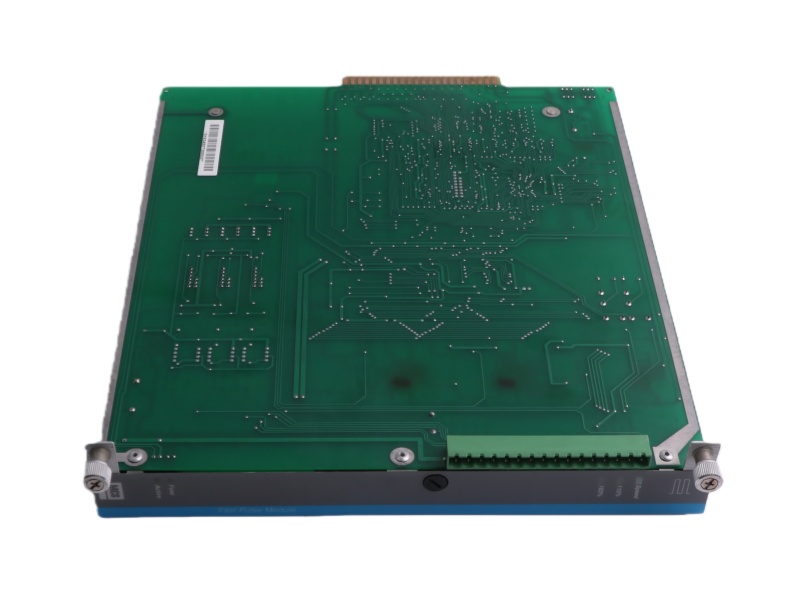

The IOP345 DIGITAL INPUT MODULE Metso is an ultra-high-density modular I/O system engineered for extreme industrial environments such as mining and cement production. It integrates 64 channels, combining both digital and analog I/O with exceptional signal integrity and predictive diagnostic capabilities. A defining feature of the IOP345 digital I/O modules Metso is its operational resilience, functioning reliably in temperatures ranging from -40°C to +70°C and offering robust protection against EMI/RFI interference, which is crucial in harsh settings like Chile’s Atacama Desert mines.

This module delivers significant operational advantages by enabling real-time monitoring and fast response, with digital inputs supporting configurable sourcing/sinking and analog inputs achieving high accuracy with cold-junction compensation. The integrated diagnostics of the Metso PLC Module IOP345 facilitate predictive maintenance, drastically reducing unplanned downtime and repair times. Its seamless integration with Metso's DNA control systems and support for protocols like OPC UA ensure quick commissioning and smooth data flow within modern industrial IoT architectures.

The practical value of the IOP345 Overspeed Trip Module METSO is demonstrated in demanding applications. For example, in a Vietnamese cement plant, its precision control over kiln feed systems enhanced product consistency and cut energy waste. Similarly, in an Italian recycling facility, its millisecond-level response time and rugged IP68/ATEX design prevented shredder jams, significantly boosting safety and uptime. These cases underscore how the Metso IOP345 translates technical robustness into tangible productivity and safety gains.

Ultimately, the DIGITAL INPUT MODULE IOP345 METSO represents a strategic investment for modernizing critical infrastructure. By consolidating I/O points, enhancing diagnostic visibility, and ensuring interoperability within the Metso ecosystem, it eliminates legacy bottlenecks. The Metso IOP345 not only safeguards against costly failures but also provides the data foundation for optimizing processes, making it a cornerstone for reliable and efficient automation in heavy industries.

For the quick assistance message us on WhatsApp at

For the quick assistance message us on WhatsApp at